The chemical name of EVA is ethylene vinyl acetate copolymer.

EVA materials have the characteristics of lightweight, waterproof, stretchable, elastic, strong solubility, and good thermal stability. It is widely used in various fields of modern industry, such as foamed shoe materials, films, wires and cables, toys, Hot-melt adhesive, various packaging materials and storage cases.

Our factory is a storage case production factory that mainly produces EVA as the raw material. So far, the products produced by our factory involve various industries. From pencil boxes for children to glasses boxes for the elderly; From Nintendo Switch cases used by game enthusiasts to the most popular VR head display storage box on the market, such as the Apple Vision PRO storage box; From Bra storage case for travel, Razor storage case, hair dryer case, digital product accessories storage case, to home coffee machine storage box, medicine storage box, Sphygmomanometer storage bag, fitness equipment storage box, etc. Products that almost require packaging can be produced using EVA through our factory.

So, how is a large, waterproof, shockproof, and sturdy EVA storage box produced? Now, I will share with you the production process of an EVA storage case suitable for Apple's latest head display MR device VISION PRO product.

If the space for storing cases needs to be separated by inner liners, a separate inner liner mold for storing cases needs to be designed and manufactured. If the space for the storage box is separated by sponges, a specialized space design for the sponges is required.

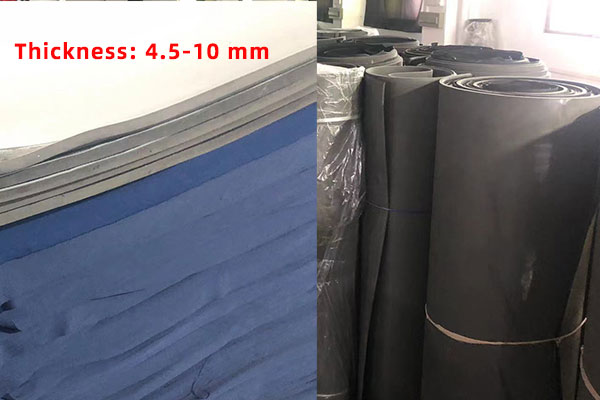

The main materials used for producing EVA storage cases include: EVA, microfiber fabric, PU leather, zippers, handles, etc. Generally, we choose EVA with the appropriate thickness based on the customer's hardness requirements for the storage box. Currently, the commonly used EVA has a thickness range of 4-10 millimeters. According to the different functions of the materials, the EVA density used for the outer layer material is higher, while the EVA density used for storing the case liner will be lower, but thicker. The current popular practice is to choose EVA with a thickness of 7.5mm for the outer shell and 10mm for the inner liner. According to customer preferences, the color of EVA materials can be black, white, or colored.

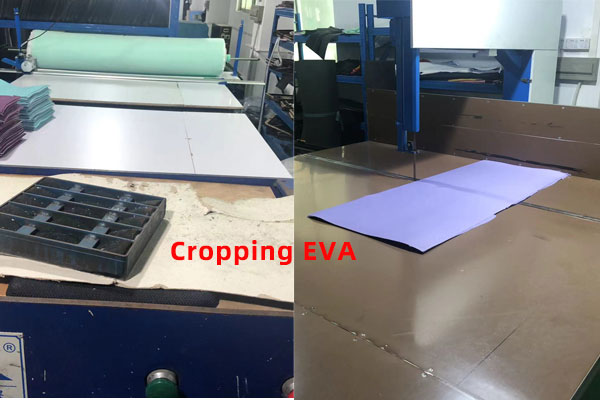

If the customer has special requirements, such as the color or pattern of the surface where the case needs to be stored, it is necessary to print the color and pattern of the surface before cutting the EVA, and use Hot-melt adhesive to tightly bond the microfiber fabric with the EVA, and then use the cutting machine to cut the EVA material according to the size required by the Vision Pro storage box. The sewing workers need to sew the zipper first. After cutting all EVA according to the required size, place them next to the storage box production machine for the convenience of the production workers.

After cutting, the EVA is made into flat plates one by one. How do workers transform flat EVA plates into storage boxes of various shapes? Due to the characteristics of EVA such as good elasticity and easy deformation when heated, we produce various shapes of storage cases to fully utilize the characteristic of EVA being easy to deform when heated. Place pieces of EVA flat plates onto different shapes of grinding tools produced, and then start the high frequency hot pressing forming integrated machine to continuously squeeze the EVA plates at a high temperature of about 170 ° C. This lasts for 20 seconds, and a main container that meets the customer's needs is formed. Then, a special cutting knife is used to repair and level the excess EVA around the main container, and a main body for storing cases is completed.

This is also the final process of producing VIsion Pro storage cases. Workers conduct quality checks on all storage cases one by one, and use special scissors to clean excess thread ends one by one. After confirming that they fully meet the product quality standards, anti pressure sponges, desiccants, etc. are placed and packaged, ready for shipment.