How to custom EVA case box? The process of developing EVA CASE BOX needs to consider multiple aspects such as material selection, design planning, size determination, and manufacturing process. Below, I will provide a detailed introduction to the steps and precautions for how to custom an EVA case box.

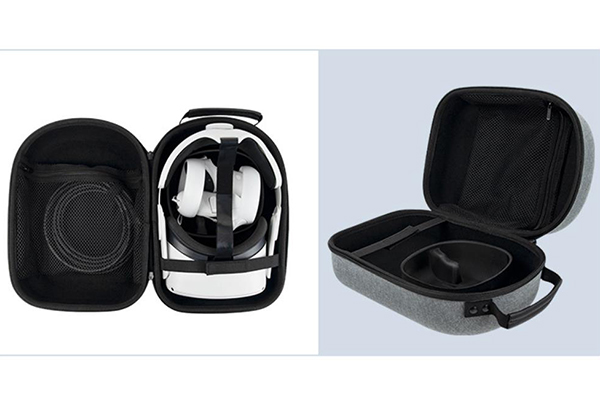

The first step is to determine the purpose and functionality of the custom EVA case box. Before customing the custom EVA Case Box, it is necessary to clarify its purpose and functions. For example, is it used to store tools, cosmetics, electronic devices, or other items? Different uses and functions will have an impact on the design and size of the custom EVA case box.

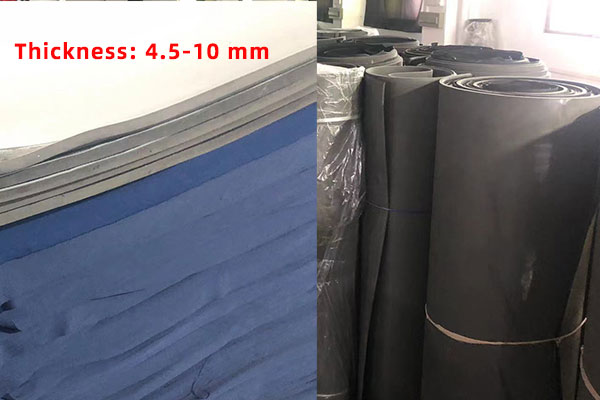

The second step is to select suitable EVA materials. EVA is an environmentally friendly, soft, shockproof, and wear-resistant material that is very suitable for making EVA case boxes. When selecting EVA materials, factors such as quality, thickness, and color need to be considered. A high-quality EVA material can provide better protection, and an appropriate thickness can increase the stability of the custom EVA case box, while the color can be selected according to demand.

The third step is to design the exterior and internal structure of the EVA case box. Design a suitable exterior and internal structure based on the purpose and functionality of the custom EVA case box. The appearance design can consider the shape, color, and decoration of the EVA case box to make it beautiful and elegant. Internal structural design can consider partition boards, small grids, or elastic bands to better organize and protect items.

Step 4, determine the size and capacity of the custom EVA case box. Determine the appropriate size and capacity based on the purpose and function of the custom EVA case box. The size should be able to accommodate the required storage items and be convenient to carry and store. The capacity should be able to meet the needs of users, not only wasting a lot of space but also being too small to put down items.

Step 5, select the appropriate manufacturing process. When developing a custom EVA case box, it is necessary to choose a suitable manufacturing process. Common manufacturing processes include mold making, cutting, gluing, and hot pressing. Choosing the appropriate manufacturing process can improve the quality and durability of EVA case boxes.

Finally, cost control and market demand also need to be considered when developing EVA CASE BOX. According to budget and market demand, reasonably control production costs to ensure that the price of custom EVA Case Box is competitive. At the same time, it is also necessary to understand market demand and design and formulate according to consumer preferences and needs.

In summary, the development of custom EVA Case box requires consideration of multiple aspects such as material selection, design planning, size determination, manufacturing process, and market demand. Through reasonable design and formulation, a powerful and reliable EVA Case box can be produced to meet the needs of consumers.